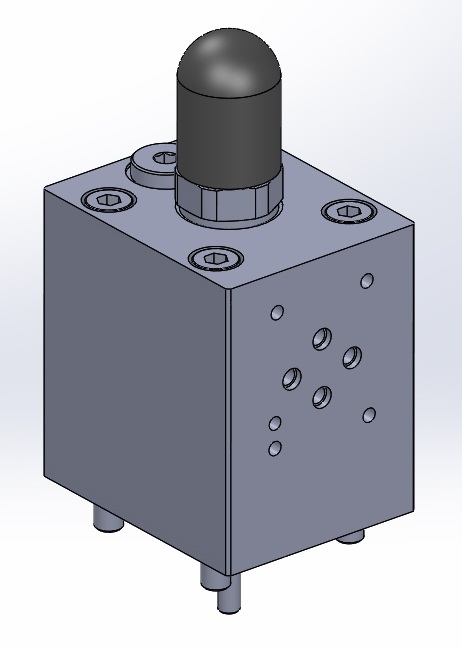

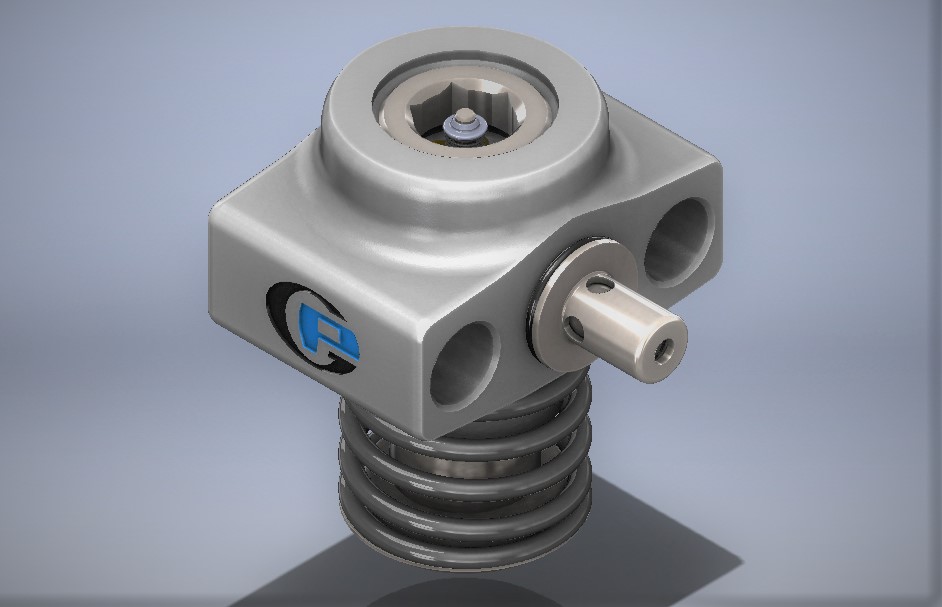

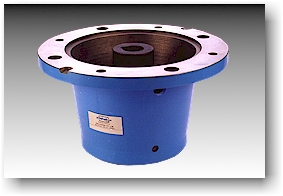

Pumping Element - 1R / 2R

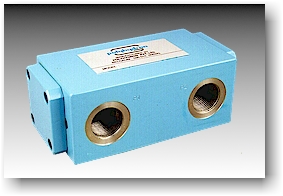

Pumping Element Assembly for 1R / 2R. Oil immersed type, open execution, face mounting, valve controlled, fixed delivery.

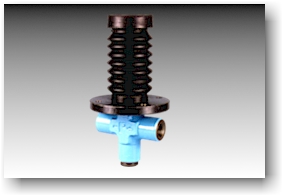

Download PDFPumping Element - 11R / 12R

Pumping element for 11R / 12R series PUMPS.

Download PDFRadial Piston Pumps - 1R2

Rugged low cost pumps with all parts renewable by replacement. Oil immersed type, open execution, face mounting, valve controlled, fixed delivery, bi-directional rotation of shaft. For coupling the pumps to the electric motors standard bell housing assemblies are available. available with two pumping elements. (Please see datasheet for additional details).

|

Nominal pressure and flow ratings |

||||||

|

Pr. bar |

550 |

450 |

350 |

300 |

250 |

200 |

|

No. of

Pumping |

Flow (l / min) @ 1450 rpm |

|||||

|

A |

B |

C |

D |

E |

F |

|

|

2 |

1 |

1.66 |

2.46 |

2.86 |

3.33 |

3.86 |

Download PDF

Radial Piston Pumps - 1R3

Rugged low cost pumps with all parts renewable by replacement. Oil immersed type, open execution, face mounting, valve controlled, fixed delivery, bi-directional rotation of shaft. For coupling the pumps to the electric motors standard bell housing assemblies are available. Available with three pumping elements. (Please see datasheet for additional details).

|

Nominal pressure and flow ratings |

||||||

|

Pr. bar |

550 |

450 |

350 |

300 |

250 |

200 |

|

No. of Pumping

|

Flow (l / min) @ 1450 rpm |

|||||

|

A |

B |

C |

D |

E |

F |

|

|

3 |

1.5 |

2.5 |

3.7 |

4.3 |

5 |

5.8 |

Download PDF

Radial Piston Pumps - 1RC / 1RCE

Radial piston arrangement, with 3, 5 or 7 pumping elements. external mounting type. Face mounting, Valve controlled, Fixed delivery. Bi-directional rotation of shaft. Available with extension shaft for through drive. With extension bracket assembly for coupling a low pressure pump having standard flange. (Please see datasheet for additional details).

|

Nominal pressure and flow ratings |

||||||

|

Pr. bar |

550 |

450 |

350 |

300 |

250 |

200 |

|

No. of Pumping

|

Flow (l / min) @ 1450 rpm |

|||||

|

A |

B |

C |

D |

E |

F |

|

|

3 |

1.5 |

2.5 |

3.7 |

4.3 |

5 |

5.8 |

|

5 |

2.6 |

4.2 |

6.2 |

7.2 |

8.4 |

9.7 |

|

7 |

3.7 |

5.8 |

8.6 |

10 |

11.7 |

13.6 |

Download PDF

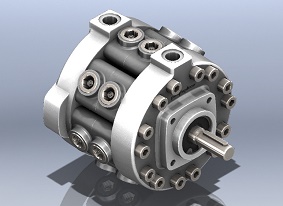

Radial Piston Pumps - 1R / 1RE

Rugged low cost pumps with all parts renewable by replacement. Radial piston arrangement, with 3, 5 or 7 pumping elements. Oil immersed type, open execution, face mounting, valve controlled, fixed delivery, bi-directional rotation of shaft. Also available with extension shaft / bracket for through drive. For coupling the pumps to the electric motors standard bell housing assemblies are available. These are also available with extension shaft to couple low pressure pumps. (Please see datasheet for additional details).

|

Nominal pressure and flow ratings |

||||||

|

Pr. bar |

550 |

450 |

350 |

300 |

250 |

200 |

|

No. of Pumping

|

Flow (l / min) @ 1450 rpm |

|||||

|

A |

B |

C |

D |

E |

F |

|

|

3 |

1.5 |

2.5 |

3.7 |

4.3 |

5 |

5.8 |

|

5 |

2.6 |

4.2 |

6.2 |

7.2 |

8.4 |

9.7 |

|

7 |

3.7 |

5.8 |

8.6 |

10 |

11.7 |

13.6 |

Download PDF

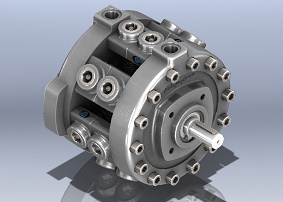

Radial Piston Pumps - 2R

Radial piston arrangement, with 3, 5 or 7

Pumping elements each per pump section. Fixed delivery, Oil immersed

type, Open execution, face mounting, Valve controlled.

Bi-directional rotation of shaft.

Flows can be combined internally, externally to feed one circuit or

used independently to feed Two circuits. (Please see datasheet for

additional details).

|

Nominal pressure and flow ratings |

||||||

|

Pr. bar |

550 |

450 |

350 |

300 |

250 |

200 |

|

No. of Pumping

|

Flow (l / min) @ 1450 rpm |

|||||

|

A |

B |

C |

D |

E |

F |

|

|

3 |

1.5 |

2.5 |

3.7 |

4.3 |

5 |

5.8 |

|

5 |

2.6 |

4.2 |

6.2 |

7.2 |

8.4 |

9.7 |

|

7 |

3.7 |

5.8 |

8.6 |

10 |

11.7 |

13.6 |

Download PDF

Radial Piston Pumps - 2RC / 2RCE

Radial piston arrangement, with 3, 5 or 7

pumping elements. External mounting type. Face mounting, Valve

controlled, Fixed delivery. Bi-directional rotation of shaft.

Available with extension shaft for through drive. With extension

bracket assembly for coupling a low pressure pump having standard

flange.

Flows can be combined internally, externally to feed one circuit or

used independently to feed Two circuits. (Please see datasheet for

additional details).

|

Nominal pressure and flow ratings |

||||||

|

Pr. bar |

550 |

450 |

350 |

300 |

250 |

200 |

|

No. of Pumping

|

Flow (l / min) @ 1450 rpm |

|||||

|

A |

B |

C |

D |

E |

F |

|

|

3 |

1.5 |

2.5 |

3.7 |

4.3 |

5 |

5.8 |

|

5 |

2.6 |

4.2 |

6.2 |

7.2 |

8.4 |

9.7 |

|

7 |

3.7 |

5.8 |

8.6 |

10 |

11.7 |

13.6 |

Download PDF

Radial Piston Pump - 11R

Radial piston arrangement, with 5 or 7 pumping elements. Oil immersed face mounting. Valve controlled. Fixed delivery. Bi-directional rotation of shaft. With extension shaft for through drive. Available with extension bracket assembly for coupling a low pressure pump having standard flange. (Please see datasheet for additional details).

|

Nominal pressure and flow ratings |

|||

|

Pr. bar |

400 |

315 |

250 |

|

No. of Pumping |

Flow (l / min) @ 1450 rpm |

||

|

A |

B |

C |

|

|

5 |

10.6 |

13.8 |

17.5 |

|

7 |

14.8 |

19.5 |

24.5 |

Download PDF

Radial Piston Pump - 11RC

Radial piston arrangement, with 5 or 7 pumping elements. External mounting type. Face mounting, Valve controlled, Fixed delivery. Bi-directional rotation of shaft. Available with extension shaft for through drive. With extension bracket assembly for coupling a low pressure pump having standard flange. (Please see datasheet for additional details).

|

Nominal pressure and flow ratings |

|||

|

Pr. bar |

400 |

315 |

250 |

|

No. of Pumping |

Flow (l / min) @ 1450 rpm |

||

|

A |

B |

C |

|

|

5 |

10.6 |

13.8 |

17.5 |

|

7 |

14.8 |

19.5 |

24.5 |

Download PDF

Radial Piston Pump - 12R

Radial piston arrangement, with 5 or 7 pumping elements each per pump section. Oil immersed face mounting. Valve controlled. Fixed delivery. Bi-directional rotation of shaft. With extension shaft for through drive. Available with extension bracket assembly for coupling a low pressure pump having standard flange. (Please see datasheet for additional details).

|

Nominal pressure and flow ratings |

|||

|

Pr. bar |

400 |

315 |

250 |

|

No. of Pumping |

Flow (l / min) @ 1450 rpm |

||

|

A |

B |

C |

|

|

5 |

10.6 |

13.8 |

17.5 |

|

7 |

14.8 |

19.5 |

24.5 |

Radial Piston Pump - 12RC

Radial piston arrangement, with 5 or 7 pumping elements each per pump section. External mounting type. Face mounting, Valve controlled, Fixed delivery. Bi-directional rotation of shaft. Available with extension shaft for through drive. With extension bracket assembly for coupling a low pressure pump having standard flange. (Please see datasheet for additional details).

|

Nominal pressure and flow ratings |

|||

|

Pr. bar |

400 |

315 |

250 |

|

No. of Pumping |

Flow (l / min) @ 1450 rpm |

||

|

A |

B |

C |

|

|

5 |

10.6 |

13.8 |

17.5 |

|

7 |

14.8 |

19.5 |

24.5 |

Bell Housing Assembly - BH (ISO)

The bell housing series BH are designed for

coupling hydraulic pumps having ISO flanges to electric motors

having metric flanges.

The correct alignment of the shafts along with the cushioned power

transmission through a resilient spider increases the life of the

bearings of the pump/motor coupled.

| Mounting Position | Axis of the assembly can be mounted in any direction |

| Pump mounting flange | As per ISO 3019/1-1975(E) |

| Motor mounting flange | As per IS 2223/IEC 72-2 |

| Flexible coupling | Spider type. |

Bell Housing Assembly (Factory Standard) - BHP

The bell housing series BHP are designed for coupling hydraulic pumps having flanges to electric motors having metric flanges. These bell housings are precisely machined to reduce misalignment of coupled shafts. The correct alignment of the shafts along with the cushioned power transmission through a resilient spider increases the life of the bearings of the pump/motor coupled. The construction also reduces the noise generation considerably.

Download PDFExtension Bracket Assembly - EB

The bell housing series EB are designed for coupling hydraulic pumps having ISO flanges to electric motors having metric flanges. These bell housing are precisely machined to reduce misalignment of coupled shafts. The correct alignment of the shafts along with the cushioned power transmission through a resilient spider increases the life of the bearings of the pump/motor coupled. The construction also reduces the noise generation considerably.

Download PDFHand Pumps - HP12 & HP16

Heavy duty construction. Renewable internal parts by replacement. Integral Relief and Release valves. Collapsible hand movement at low pressure. (Please see datasheet for additional details).

|

Nominal flow and pressure ratings |

|||

|

Model |

Max. working |

Flow capacity |

Oil tank |

|

HP12 |

700 |

2.8 |

1.2 |

Hand Pumps with Rotary Directional Control Valves - HP*-D

Hand pump model HP*-D are compact heavy duty pumps designed for industrial applications like operating small presses, fixtures as well as providing source of oil for hydraulically operated emergency equipments. These hand pumps are equipped with integral Rotary Directional Control Valve with two outlet ports for switching of the flow between the two sides of a double acting cylinder. The Rotary valve has pressure holding ability.

Download PDFHand Pumps (Tank Side Mounting) - HPTS12, HPTS16 & HPTS12-1000

Hand pumps series HPTS** are identical in specifications to series HP** pumps, except that, these pumps are meant for mounting on the side wall of oil reservoir / tank of a hydraulic system and therefore can be integrated into the main system as a stand-by pump or can be used as a power source for cylinders or jacks which need large volume of oil for their actuation by mounting them on side wall of suitably designed oil tank.

Download PDFFeed and Power Hand Pumps - HP5012 & HP5016

Automatic change-over from high discharge at low pressure to low discharge at high pressure. Renewable internal parts by replacement. Collapsible Hand lever for compact size and short hand movement.

Download PDFFeed and Power Hand Pumps (with small tank) - HP5012-ST & HP5016-ST

Automatic change-over from high discharge at low pressure to low discharge at high pressure. Renewable internal parts by replacement. Collapsible Hand lever for compact size and short hand movement.

Download PDFFEED AND POWER HAND PUMP Model : HP5012**D / HP5016**D

These hand pumps are provided with integrated Rotary Directional Control Valves with two outlet ports for switching of the hand pump power between the two sides of a double acting cylinder. (Please see datasheet for additional details).

Download PDFDirect Operated Pressure Relief Valve - DPR

Direct acting with guided cushioned poppet. Available in Cartridge, Threaded and Subplate types.

|

Nominal pressure and flow ratings |

||

|

Model |

Max.

working |

Max.

flow |

|

DPR 06 |

700 |

30 |

|

DPR 10 |

400 |

80 |

|

DPR 20 |

400 |

160 |

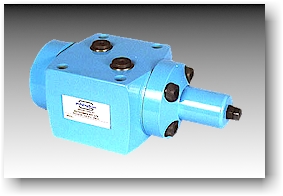

Direct Operated Pressure control Valve - DPC

Hydraulically cushioned valves, used to control sequencing, relieving, unloading or counter-balancing operations.

Download PDFDirect Operated Pressure reducing Valve - DPM

Direct acting construction with built-in pressure relief for secondary port.By-pass Check Valve optional.

|

Nominal flow and pressure ratings |

|

| Max. flow handling capacity |

20 l/min. |

| Max. setting pressure |

200 bar |

| Max. working pressure |

315 bar |

Direct Operated Pressure sequence Valve - DPS 06

Direct acting spool type pressure sequence valve. Models available :

Internal pilot, internal drain.

External pilot, internal drain.

Internal pilot, external drain.

External pilot, external drain.

Port A normally connected to port T : control at port P port A

normally connected to port T : control at port B Four pressure

ratings 25, 50, 100, or 200 bar.For reverse free flow, optional

check valve can be supplied as a stackable module. Pressure

adjustment by screw or hand knob.

|

Nominal flow and pressure ratings |

|

| Max. flow handling capacity |

25 l/min. |

| Max. setting pressure |

200 bar |

| Max. working pressure |

315 bar |

Pilot Operated Pressure Relief Valves (Cartridge Type) - PPR 06K

Two stage Spool type Relief / Reducing Valve Cartridge Low pressure

override due to larger flow area.

Two options for pressure adjustment,

- With set screw and lock nut.

- With hand knob and lock nut.

Internal drain valves can be converted to external drain.

| Nominal flow and pressure ratings | |

| Max. flow handling capacity |

30 l/min. |

| Max. setting pressure |

315 bar |

| Max. working pressure |

315 bar |

Pilot Operated Pressure Reducing Valves (Cartridge Type) - PPM 06K

Two stage Spool type Relief / Reducing Valve Cartridge Low pressure

override due to larger flow area.

Two options for pressure adjustment,

- With set screw and lock nut.

- With hand knob and lock nut.

| Nominal flow and pressure ratings | |

| Max. flow handling capacity |

30 l/min. |

| Max. setting pressure |

200 bar |

| Max. working pressure |

315 bar |

Pilot Operated Pressure Relief Valve (Modular Construction) - MPPR 06

Pilot operated pressure relief valve modular construction for

vertical stacking assemblies.

For Cartridge Valve details refer p09605

Interface conforming to ISO 4401 - AB - 03 -04 - A, IS 10187, DIN

24340

Four models available.

|

Nominal flow and pressure ratings |

|

| Max. flow handling capacity |

30 l/min. |

| Max. setting pressure |

315 bar |

| Max. working pressure |

315 bar |

Pilot Operated Pressure REDUCING Valve (Modular Construction) - MPPM 06

Pilot operated pressure reducing valve modular construction for

vertical stacking assemblies.

For Cartridge Valve details refer p09605

Interface conforming to ISO 4401 - AB - 03 -04 - A, IS 10187, DIN

24340

Four models available.

|

Nominal flow and pressure ratings |

|

| Max. flow handling capacity |

30 l/min. |

| Max. setting pressure |

315 bar |

| Max. working pressure |

315 bar |

Pilot Operated Pressure Relief Valves - PPR

Pilot operated seat type valve. High flow handling capacity, low pressure override, remote controllability and solenoid unloading possibility are the main features of these valves. Bodies available with threaded ports or sub-plate mounting style.

| Nominal flow and pressure ratings | ||

| Model |

Max. working

pr. (bar) |

Max. flow

(l/min) |

| PPR 10 | 315 | 100 |

| PPR 20 | 315 | 200 |

| PPR 30 | 315 | 400 |

Pilot Operated Pressure Relief cum Unloading Valve - PPRU

Two stage poppet type Relief cum unloading valve. Additional solenoid unloading facility as an optional feature. Three standard sizes - 10, 20, & 30.

| Operating Pressure |

For

port 'A', 'X' and 'P' --- 315 bar For port 'B' ----- 60 bar |

| Max. flow handling capacity |

For

Valve Size 10 -------- 100 l/min. 20 -------- 200 l/min. 30 -------- 400 l/min. |

Pilot Operated Pressure reducing Valve - PPM

Two stage pilot operated construction. These valves are normally open type valves. When the pressure in the secondary port ( port B ) increases to set pressure, the valve closes against the spring.

| Size |

Max. Working

Pr.(Inlet) |

Reduced Pr. |

Max. flow

(l/min) |

| PPM10 | 315 |

adjustable

upto 5 to 315 |

80 |

| PPM20 | 200 | ||

| PPM30 | 300 |

Pressure Control Modules - PCM 06-06

Designed to control double pumps of a Hi-Low system. Unloads low pressure pump when system pressure rises above the pressure set on unloader valve. Relieves high pressure pump when system pressure reaches the value.

|

Nominal flow and pressure ratings |

||||

|

Model |

Max. pr.

for |

High pr.

|

Max. pr.

For |

Low pr.

|

|

PCM 06-06 |

400 |

25 |

50 |

25 |

Pressure Control Modules - PCM 20

Designed to control Double pumps of a Hi-Low system. Consists of a High pressure relief valve, a Check valve and a low pressure unloading valve. Unloading of pumps by Solenoid valve / Valves as an optional feature.

|

Nominal flow and pressure ratings |

||||

|

Model |

Max. pr.

for |

High pr.

|

Max. pr.

For |

Low pr.

|

|

PCM20-06 |

315 |

25 |

100 |

160 |

|

PCM20-10 |

315 |

60 |

100 |

160 |

Pressure Control Modules - PCM 20-16

Designed to control Double pumps of a Hi-Low system. Consists of a High pressure relief valve, a Check valve and a low pressure unloading valve. Unloading of pumps by Solenoid valve / Valves as an optional feature.

|

Nominal flow and pressure ratings |

||||

|

Model |

Max. pr.

for |

High pr.

|

Max. pr.

For |

Low pr.

|

|

PCM20-16 |

315 |

100 |

100 |

160 |

Counter Balance Valve - CB

Counter balance valves are seat type valves. They offer free-flow from their port B to A and give leak free closure in opposite direction upto a predetermined pressure. This predetermined cracking pressure can be adjusted within its maximum specified range.

| CBS10T | CBS20T | |

| Flow handling capacity | 30 lpm | 115 lpm |

Counter Balance Valve - CB Design series 30

Counter balance valves are seat type valves. They offer free-flow from their port B to A and give leak free closure in opposite direction upto a predetermined pressure. This predetermined cracking pressure can be adjusted within its maximum specified range.

| Flow handling capacity | 200 lpm |

| Max. Set Pressure | 50 bar |

| Operating pressure | 315 bar |

Direct Operated Pressure control Valve - DPC

Hydraulically cushioned valves, used to control sequencing, relieving, unloading or counter-balancing operations.

|

Nominal flow and pressure ratings |

|

| Max. flow handling capacity |

160 l/min |

| Max. setting pressure |

160 bar |

| Max. working pressure |

350 bar |

Rotary Directional Control Valve - 4RDL02

A lever operated rotary type directional control valve is generally used for high pressure applications at low flow. These valves are used where leak-free closure is required.

Lever Operated Directional Control Valve (Old Series) - DL10 ( Series 10 )

Completely encapsulated control mechanism for protection against dirt. Five chamber design. Flexibility in rotating the operating mechanism by 90° x 4. Wide variety of spools available in subplate model only.

|

Nominal flow and pressure ratings |

||

|

Model |

Max. working pr. (bar) |

Max. flow l/min. |

|

4DL 10 |

Port P, A and B .....

350 Port T ................ 100 |

100 |

Lever Operated Directional Control Valve - DL20

Completely encapsulated control mechanism for protection against dirt. Five chamber design. Wide variety of spools available both in subplate and threaded model

Download PDFPilot Operated Directional Control Valve (New Series) - DP 10

Pilot operated directional control valves are hydraulically operated spool valves. They control the start, stop & direction of fluid flow. Available in 19 spool configurations. Available as spring centered and spring offset. Mounts on standard ISO 4401, IS10187.

|

Nominal flow and pressure ratings |

||

|

Model |

Max. working pr. (bar) |

Max. flow l/min. |

|

4DP 10 |

Port P,

A and B ......

350 Port T ................... 250 Port X and Y .......... 150 |

120 |

Lever Operated Pressure Holding D.C.V. - DLS 10, DLS 20

Designed for single acting cylinders which are supposed to hold pressure. Ensures smooth decompression prior to return of the cylinder ram. Large return oil passage to reduce pressure drops, allowing rams to return under low external forces. Valves can be connected in series for independent multiple single acting cylinder operations.

Solenoid Pilot Operated Pressure Holding D.C.V. - DES 10, DES 20

Designed for single acting cylinders which are supposed to hold

pressure.

Specially suitable for rubber moulding presses. Ensure smooth

decompression prior to return of the cylinder ram. Available as

standard & Quick Exhaust. Large return oil passages allows rams to

return under low external forces. Valves with quick exhaust feature

have 2.34 times larger return passages. Provided with manual opening

in case of power failures.

Valves can be connected in series for independent multiple single

acting cylinder operations. The valve is actuated by a solenoid

controlled pilot.

| Flow passage areas |

Valve |

Model |

P to A |

B to T |

|

Standard |

4DES20A |

3.1 cm² |

5.3 cm² |

|

|

With quick |

4DES20A |

3.1 cm² |

12.4 cm² |

|

| Operating Pressure |

For ports P, A, B, C,

G --- 350 bar |

|||

| Pilot Pressure | 35 bar. | |||

Solenoid Operated Directional Control Valve (CETOP 03) - DE 06 (315 bar, 63 lpm)

Direct solenoid operated, spool type, mounting on ISO 4401-03-02.

Five chamber body and spool design provides low-pressure drop, with

maximum performance. Balanced spool design ensures proper shifting

force for maximum reliability and long life. All spools and bodies

are interchangable, simplifying maintenance. Wet pin DC solenoids

ensure better heat dissipation, quitter operation, there by

increasing solenoid life. Moulded solenoid coils eliminate moisture

problems and ingress of dust. Plug-in-coils for ease of maintenance.

Indicator lights are a standard option.

Solenoid Operated Directional Control Valve (CETOP 05) - DE 10 (315 bar, 120 lpm)

4-port, spool type, solenoid operated, directional control valves with wet armature AC or DC coils and wide variety of spool types with spring centered and spring-offset arrangements.

- Five chamber body and spool design to facilitate high flow.

- Conforms to ISO4401-5, NFPA T3.5.1M R1 and ANSI B93-7 D 05 interface.

- Available in 52 standard, interchangeable spool configurations.

- Removable wet-armature AC and DC solenoids for quick replacement and conversions. Moulded solenoid coils to protect against moisture and ingress of dust.

- Individual solenoid plug-in connectors with indicator lights to ISO 4400 and DIN 43650.

- Special R-rings for high extrusion resistance. Increased stability under high dynamic condition.

- Override for operation of valve without electrical power.

Note on solenoid identification : Solenoid "a" is close to Port "A" and Solenoid "b" is close to Port "B" for a direct operated valve.

Lever Operated Directional Control Valve (CETOP 03) - DL 06

Completely encapsulated mechanism for protection against dirt. Five chamber design for better reduction in dynamic forces and longer valve life. Available as spring centered, spring off-set or detented model. Operating head can be rotated by 90° x 4 around spool axis for flexibility in mounting. Valve mounting interface conforms to ISO 4401-03-02. Five chamber body and spool design provides low-pressure drop, with maximum performance. Balanced spool design ensures proper shifting force for maximum reliability and long life. All spools and bodies are interchangable, simplifying maintenance.

Lever Operated Directional Control Valve (CETOP 03) - DL 06**-11 (New Series)

4-port, spool type, directional control valves with hand lever actuation and wide variety of spool types with spring-centered, spring-offset and detent arrangements.

Pilot Operated Directional Control Valve - DP 20

Pilot operated directional control valves are hydraulically operated spool valves. They control the start, stop & direction of fluid flow. Available in 19 spool configurations. Available as spring centered and spring offset. Mounts on standard ISO 4401, IS10187.

|

Nominal flow and pressure ratings |

||

|

Model |

Max. working pr. (bar) |

Max. flow l/min. |

|

4DP 20 |

Port P, A,

and B .......

350 Port T ...................... 250 Port X and Y ............. 150 |

300 |

Solenoid Pilot Operated Directional Control Valve - DEP 20

Available as spring centered, spring offset Valve mounting interface conforms to International and National standards. Minimum pilot pressure is 5 bar.

|

Nominal flow and pressure ratings |

||

|

Model |

Max. working pr. (bar) |

Max. flow l/min. |

|

4DEP20 |

Port P, A, B and X

............... 350 Port T (with internal drain) ... 160 Port T (with external drain) .. 250 Port Y ............................... 160 |

300 |

Lever Operated Directional Control Valve - DL20

Completely encapsulated control mechanism for protection against dirt. Five chamber design. Wide variety of spools available both in subplate and threaded model.

|

Nominal flow and pressure ratings |

||

|

Model |

Max. working pr. (bar) |

Max. flow l/min. |

|

4DL20 |

Port P, A and B .....

350 Port T (with internal drain) .. 100 Port T (with external drain) .. 250 |

300 |

Solenoid Operated Cartridge Directional Control Valve - CDE 06

- Solenoid operated cartridge type directional control valve.

- Sliding spool construction.

- Wet pin solenoids ensure better heat dissipation, quieter peration, there by increasing solenoid life.

- Moulded solenoid coils eliminate moisture problems and ingress of dust.

- Plug-in-coils for ease of maintenance.

- Indicator lights are a standard feature.

Solenoid Operated Directional Control Valve (CETOP 05) - DE10-LP (210 bar, 100 lpm)

4-port, spool type, solenoid operated, directional control valves with wet armature AC or DC coils and wide variety of spool types with spring centered and spring-offset arrangements.

- Five chamber body and spool design to facilitate high flow.

- Conforms to ISO4401-5, NFPA T3.5.1M R1 and ANSI B93-7 D 05 interface.

- Available in 52 standard, interchangeable spool configurations.

- Removable wet-armature AC and DC solenoids for quick replacement and conversions.

- Moulded solenoid coils to protect against moisture and ingress of dust.

- Individual solenoid plug-in connectors with indicator lights to ISO 4400 and DIN 43650.

- Special R-rings for high extrusion resistance. Increased stability under high dynamic condition.

- Override for operation of valve without electrical power.

Note on solenoid identification : Solenoid "a" is close to Port "A" and Solenoid "b" is close to Port "B" for a direct operated valve.

Pressure compensated flow control valve - PF

Pressure compensated. Check valve option for reverse-free flow. Four rotations of hand knob to facilitate the setting with ease. Thumb screw provision to retain valve setting. Stroke limiter available as an option.

| Max. working pr. | 315 bar |

|

Flow controlling capacity |

Minimum 0.25 to 4 l/min, 0.5 to 8 l/min, 1 to 16 l/min, 2 to 32 l/min or 3 to 40 l/min. |

Flow divider valve - FD

Flow divider valves provide dual flow from a single source at a predetermined ratio, regardless of load. Maximum dividing error is 5%, Threaded port body.

|

Inlet Flow |

5 -10 |

10 -18 |

15 -30 |

30 -100 |

|||

|

Max. Pr. (bar) |

315 |

||||||

|

Dividing Ratio (%) |

50 : 50 |

||||||

Throttle / Check Valve (Modular) - TCM 06

Double throttle cum check, non pressure compensated, modular construction. Can be used as Metering-in or Metering-out device.

|

Nominal flow and pressure ratings |

||

|

Model |

Max.

working |

Max.

flow |

|

TCM 06 |

315 |

40 |

Throttle / Check Valve (Modular) - TCM 10

Double throttle cum check, non pressure compensated, modular construction. Can be used as Metering-in or Metering-out device.

|

Nominal flow and pressure ratings |

||

|

Model |

Max.

working |

Max.

flow |

|

TCM 10 |

315 |

100 |

Throttle / Check Valve (Modular) - 2TCL10 -- (New Product)

Double throttle cum check, 2TCL10 are meant for controlling flow in one direction in circuit by simple throttling of flow. Reverse flow is free and is independent of throttle condition in opposite direction in same path.

Download PDFCheck Valve - C

These seat type valves allow free flow from port A to port B and give leak-proof closure in opposite direction. Available as inline mounting or Sub-plate mounting as per factory & ISO standards.

|

Nominal flow and pressure ratings |

|||||||

|

Model |

C06 |

*C08 |

C10 |

*C15 |

C20 |

*C25 |

C30 |

|

Max.

working |

315 |

315 |

315 |

315 |

315 |

315 |

315 |

|

Max.

flow |

10 |

20 |

30 |

80 |

120 |

220 |

280 |

|

* : Available only in threaded type. |

|||||||

Check Valve - C (ISO)

Seat type valves. Allow free flow from port A to port Band offer

leakage free closure in opposite direction. Available in four sizes

of standard interfaces conforming to

ISO 5781

IS 10187

DIN 24340

Each model available with options of four cracking pressures :

0.5, 1.5, 3 and 5 bar.

Check Valve - CI

Seat type valves, Model CI with internal drain. Threaded or Sub-plate mounting construction. Available with two pilot piston size options only for Model CI.

|

Nominal flow and pressure ratings |

||

|

Model |

Max.

working |

Max.

flow |

|

CI10 |

315 |

80 |

|

CI20 |

315 |

160 |

|

CI30 |

315 |

350 |

Check Valve - CI06

Seat type valves, Model CI with internal drain. Threaded or Sub-plate mounting construction. Available with two pilot piston size.

|

Nominal flow and pressure ratings |

||

|

Model |

Max.

working |

Max.

flow |

|

CI06 |

700 |

30 |

Check Valve - CL

Seat type valves, CL with external drain. Threaded or Sub-plate mounting construction.

|

Nominal flow and pressure ratings |

||

|

Model |

Max.

working |

Max.

flow |

|

CL10 |

315 |

80 |

|

CL20 |

315 |

160 |

|

CL30 |

315 |

350 |

Check Valve - 2CI

These valves are available with the pilot operated check valve

facility on either A or B or both A and B threaded ports.

The hydraulic opening operation for free flow in reverse direction

is achieved by means of internal pilot pressure available from the

other working port.

By-pass Check Valve (Modular) - BCM

Seat type modular valve. Intended for by - passing. Pressure control valve,Pressure reducing valve etc. to achieve reverse free flow condition.Allow free flow from port A to port B or from port B to port A ( see model code ) and offer leakage free closure in opposite direction. Available in four sizes of standard interfaces conforming to ISO 5781, DIN 24340 or IS 10187 Each model available with options of four cracking pressures : 0.5, 1.5, 3 and 5 bar.

| Size |

Max.

operating pressure |

Flow

handling capacity l/min |

|

06 10 |

315 bar |

20 50 |

Pilot operated check valve (Modular) - CIM 06

These modular valves are available with the pilot operated check

valve facility on either 'A' or 'B' ports. The hydraulic opening

operation for free flow in reverse direction is achieved by means of

internal pilot pressure available from the other working port.

Interface conforming to

ISO 4401-AB-03-04-A

IS 10187

DIN 24340

To ensure proper closure of both valve poppets, both user

connections should be unloaded when the control valve is in the

neutral by connecting with the return line.

|

Nominal flow and pressure ratings |

||

|

Model |

Max.

working |

Max.

flow |

|

CIM 06 |

315 |

35 |

Pilot operated check valve (Modular) - CIM 10

These modular valves are available with the pilot operated check

valve facility on either A or B or both A and B ports. The hydraulic

opening operation for free flow in reverse direction is achieved by

means of internal pilot pressure available from the other working

port.

To ensure proper closure of both valve poppets, both user

connections should be unloaded when the control valve is in the

neutral position by connecting with the return line.

|

Nominal flow and pressure ratings |

||

|

Model |

Max.

working |

Max.

flow |

|

CIM 10 |

315 |

80 |

Shuttle Valves - SL

Seat type construction. Automatically connects it's P port to either A or B depending upon whichever of the two ports is at higher pressure level. Isolates port A and B from each other. Port P gets connected to tank, only if, port A and port B are connected to tank. Available both in Threaded and Sub-plate type.

|

Nominal flow and pressure ratings |

||||

|

Model |

Max. working pr. (bar) |

Nominal

flow |

||

|

SL |

315 |

30

l/min. at

7.5 |

||

Prefill valve ( PV 32 - 80 )

Intended for prefilling and exhausting of large hydraulic cylinders. Can be used as anticavitation check valves. Decompression feature is optional up to size 80.

|

Nominal flow and pressure ratings |

|||

|

Model |

Max.

working |

Max. flow l/min. |

|

|

Prefilling |

Exhausting |

||

|

PV

32 |

315 |

96 |

216 |

|

PV 40 |

315 |

152 |

304 |

|

PV 50 |

315 |

236 |

472 |

|

PV 63 |

315 |

372 |

744 |

|

PV 80 |

315 |

608 |

1216 |

Prefill valve ( PV 100 - 200 ) - 21 Series

The Prefill Exhaust Valve (PV) is a hydraulic-pilot operated check

valve with seat type construction. It allows free flow from port A

to port B. Flow from port B to port A can be enabled by applying

pilot pressure to it's port X.

The decompression feature enables the valve to open in two stages

progressively, allowing smooth and rapid exhaust of the compressed

oil. Opening and closing time of the valve can be influenced by

providing Throttle-Check Valves in the X port line.

Flanged port A of the valve housing can be rotated around vertical

axis through 360° to facilitate access to flange fixing bolts and

flange orientation

Features

- Integrated Seat provides high rigidity, high fatigue resistance and less deflection of the flange.

- Encapsulated O-ring allows easy of assembly and prevents o-ring damage during assembly.

- Simplified Cavity machining

- Larger suction flange to reduce pressure drop in the suction line and consequently increase flow handling capability

- Improved Pilot cylinder sealing to minimize pilot leakage and reduce frictional loss during operation.

|

Nominal flow and pressure ratings |

|||

|

Model |

Max.

working |

Max. flow l/min. |

|

|

Prefilling |

Exhausting |

||

|

PV 100 |

315 |

940 |

1880 |

|

PV 125 |

315 |

1480 |

2960 |

|

PV 150 |

315 |

2120 |

4240 |

|

PV 200 |

315 |

3800 |

7600 |

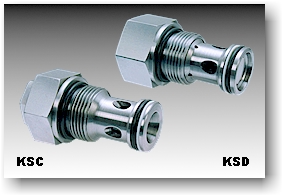

Check Valve, SCREW-IN CARTRIDGE - KSC / KSD

Two port screw-in cartridge valves that are designed to fit in a

cavity confirming to ISO 7789 : 1998 (E). These are seat type vales,

available in four different sizes and with five different cracking

pressure in each size.

Check valves allow free flow in one

direction while providing leak-free closure in reverse direction.

Features

- Fits into ISO 7789 : 1998 (E) cavity. (other cavities available on request)

- Cartridge construction for compact integrated manifolds

- Economical

- Quick and Easy field service, reduces down time

- Valve Bodies available on request

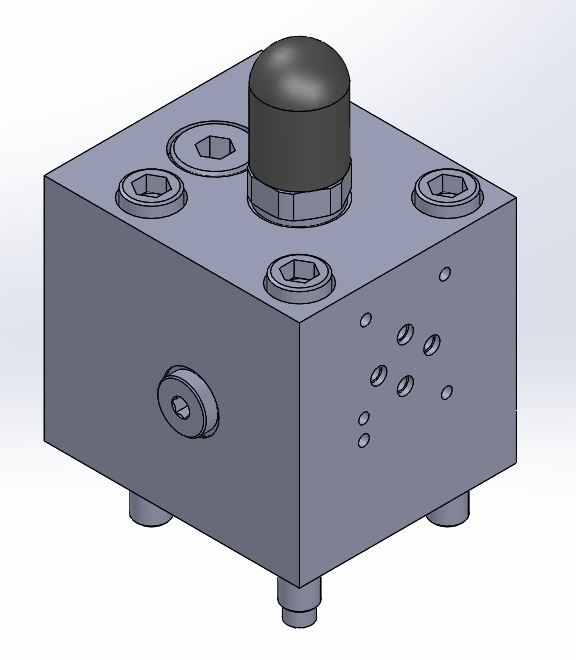

Cartridge Valves - CV 16 to CV 40

These valves are suitable for mounting in manifold cavities machined as per ISO 7368. By selecting suitable cartridge and cover, it is possible to achieve functions like Check valve, Directional control valve, Unloading valve, Throttle valve etc. These valves offer fast response, have very low internal leakage and can handle very large flow rates. The cartridges are available with two area ratios.

|

Nominal flow and pressure ratings |

||||||||

|

Model |

CV 16 |

CV 25 |

CV 32 |

CV 40 |

||||

|

Max.

working |

350 |

350 |

350 |

350 |

||||

|

Max.

flow |

160 |

400 |

600 |

1000 |

||||

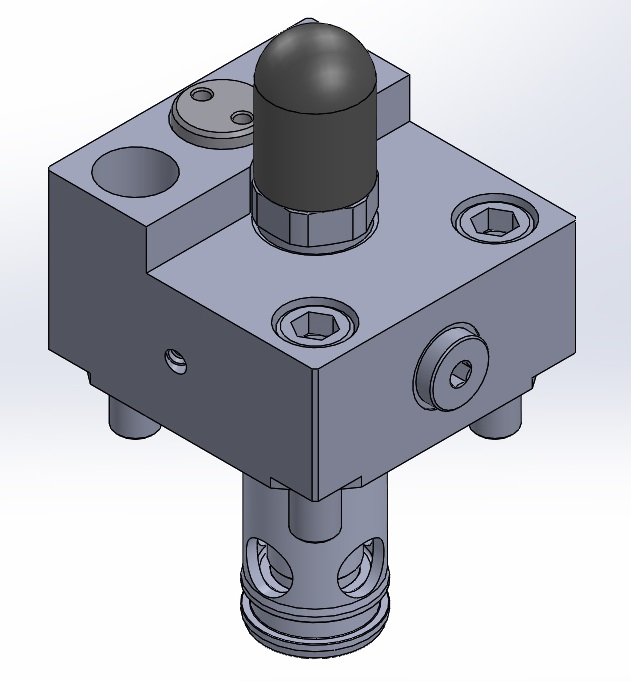

Two Port Slip-In Cartridges ISO 7368 - CV 50 to 100

Slip in cartridge valves are two port valves that can be inserted

into compact manifold control blocks, having cavities that are

machined as per ISO 7368. The function of the cartridge valve

depends on the type of control cover used. With the help of suitable

control cover the cartridge valve can assume pressure, directional,

throttling or combination of these function.

Cartridge valves are available in two area ratios and four cracking

pressures. Depending upon the function required, cartridge valve

having Suitable area ratio must be used.

The control covers will have to be ordered separately.

|

Nominal flow and pressure ratings |

||||||||

|

Model |

CV 50 |

CV 63 |

CV 80 |

CV 100 |

||||

|

Max.

working |

350 |

350 |

350 |

350 |

||||

|

Max.

flow |

1900 |

2700 |

4600 |

7400 |

||||

Joystick Controlled - 4JP 06

4JP 06 Joystick Controlled Pilot Oil Unit is a Manual Joystick control valve, meant for providing variable pilot pressure to the hydraulic components like Proportional Pilot Operated Directional Control Valves, Pumps and motors etc., which need variable pilot pressure to control their outputs. The valve has two pairs of outlets, which can be operated independently or in tandem. Depending upon the Joystick tilt, the valve provides variable pressure to one or two of its outlets at a time. The pilot pressure can be regulated in the pressure range of 6 to 19 bar.

Currently we are supplying this valve to - All Customers

Download PDFJoystick Controlled - JP 10

Pilot oil unit series 4JP are intended for giving sensitive pressure signals to pumps, Valves or Hydraulic motors which need to be controlled by remote pilot pressure. Functioning of these valves is based on spool type direct acting pressure reducing valve principle.

|

Nominal flow and pressure ratings |

|||||

|

Model |

Max. working |

Pr. Range |

Deflection |

Pilot oil |

Hysterises |

|

JP |

Input pr. --> 50 |

6 to 15 |

4° to 25° |

16 l/min. |

1 bar |

| Pr. at port T --> 3 |

6 to 26 |

||||

Brake Valve (Developed for OEM Customers)

Currently we are supplying this valve to

L&T John Deere for Tractors

Telcon for Tata - John Deere Back Hoe Loaders.

Lock Valve (Developed for OEM Customers)

Lock valve, basically two position directional control valve

designed to have flexibility in diverting the flow. The valve is

provided with single pump connection, three common ports designated

as 'A' and four common tank ports designated as 'T'. In normal

position, pump flow is connected to A ports and at an angle in

between 78° - 100° port A is connected to tank with throttling

effect.

Currently we are supplying this valve to

Telcon for Tata - Hitachi Excavators.

Side Shift Lock Valve (Developed for OEM Customers)

Currently we are supplying this valve to

Telcon for Tata - John Deere Back Hoe Loaders.

Tipper Valve (Developed for OEM Customers)

Currently we are supplying this valve to

Hyva India.

Shockless Valve (Developed for OEM Customers)

Currently we are supplying this valve to

Telcon

Travel Pilot Valve (Developed for OEM Customers)

Earlier this valve was being supplied to - Tata Hitachi

FOOT PUMP - FP

Heavy duty construction with hardened and ground plunger. Both suction and delivery valve seats are replaceable. Intended for supply of lubricating oil or pilot pressure.

Download PDFManifold for D.C.V. - CETOP- 4.2 - A - 05(P)

Designed specially for multistation directional control valves, CETOP- 4.2 - A - 05(P). Number of stations vary from minimum 2 to maximum 7.

Download PDFManifolds For Directional Control Valves - ( 1P 02155* )

Designed specially for multistation directional control valves,

CETOP- RP 35 H size 3.

Number of stations vary from minimum 2 to maximum 10.

Pressure Switch - 1PS

Non adjustable differential type. Spring loaded sealed piston construction. Encapsulated design for protection against dust. Six pressure ranges available, which can be adjustable upto 10, 50, 100, 200, 350 and 420 bar. Transparent plug-in connector is available with LED

|

Model |

Max.

Operating |

Pr. Range |

|

1PS |

420 |

Adjustable upto |

Return Line Filter - RF

Threaded type and Sub-plate mounting style. Paper element as filtration media. Spin-on disposable canisters. Integral by-pass check valve.

| Nominal flow and pressure ratings | |||

| Model |

Max. working

pressure |

Flow

handling capacity |

Filtration

capacity |

| RF | 7 bar | 40 l/min. | 25 microns |

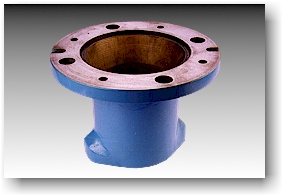

Foot Valve

These valves are recommended , when the pumps are installed with negative suction head. Threads for the Foot valve are sized to provide approximately 3 times larger capacity of the strainer. Strainer is not included in the scope of supply.

Download PDF

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)